BIS (ISI) Certification for Chemicals

Introduction to BIS Certification for Chemicals

The establishment and upkeep of standards in a variety of sectors, including chemicals, are the responsibility of the Bureau of Indian Standards (BIS), a national organization of India founded in 1986. Granting ISI (Indian Standards Institute) certification to chemical goods that fulfill the stipulated safety, quality, and reliability requirements is one of the main duties of BIS.

Chemical BIS (ISI) Certification

Pharmaceuticals, textiles, paints, and coatings are just a few of the sectors that heavily rely on chemicals. To avoid any negative effects on the environment and human health, it is crucial to make sure that these chemicals adhere to the necessary quality and safety requirements.

In India, BIS (ISI) Certification for Chemicals is mandatory. It guarantees that the chemicals produced and marketed in India adhere to the guidelines established by BIS. BIS-approved labs undertake a number of tests and inspections as part of the certification process to ascertain the chemicals' quality, safety, and dependability.

ISI accreditation for chemicals is important

For many chemical goods, including acids, bases, solvents, and other industrial chemicals, ISI Certification is required as a guarantee of the products' dependability, safety, and high quality. In addition to giving producers a competitive edge, ISI Certification fosters confidence and trust among stakeholders and consumers. Moreover, it decreases the risk of legal and financial penalties by assuring the regulatory agencies that the items fulfill the necessary safety requirements.

Advantages of Chemical BIS (ISI) Certification

Compliance with Regulatory Requirements: In India, BIS (ISI) Certification for Chemicals is mandatory. It guarantees that the chemicals produced and marketed in India adhere to the guidelines established by BIS. This certification guarantees adherence to the legal and regulatory standards, which may aid in avoiding problems with the law and fines.

Better Quality and Safety: BIS (ISI) Certification for Chemicals verified the necessary quality and safety criteria. The quality and safety of chemicals are improved thanks to this accreditation, which may raise customer satisfaction and lower the likelihood of accidents.

Improved Marketability: BIS (ISI) Certification for Chemicals are guarantees that the chemical product is of high quality. It aids in making chemicals more marketable, which may result in more sales and profits. Also, the accreditation contributes to the manufacturer's legitimacy, which may assist win over consumers' confidence.

Competitive Advantage: Chemical firms that have their products BIS (ISI) certified have an edge over their rivals. The accreditation helps in proving the manufacturer's dedication to quality and safety. This may aid in both bringing in new clients and keeping hold of current ones.

Environmental Protection: BIS (ISI) Certification for Chemicals is guaranteed to adhere to the established environmental criteria when manufactured and marketed in India. By avoiding any negative effects on human health and environmental protection, this accreditation is beneficial.

Basic Criteria to Get BIS Certificate

Please note the below points:

- Applicant has to find the applicable Indian standard (IS) before filing the application.

- BIS issue the ISI Certificate only to the manufacturing unit (Where a finished product is manufactured)

- BIS does not issue the license to the importer / distributor / retailer.

- If the applicants have multiple factories in different locations, then they have to file separate applications for each factory address.

- Manufacturer has to show the process chart of manufacturing from receiving the raw material to final packaging. If some part of manufacturing is outsourced, BIS clearance must be required.

- Applicant (Manufacturer) has to ensure that they have all required testing equipment and qualified Quality control personal (QCI) to perform the according to the applicable Indian standard and SIT.

Mandatory Product List for BIS (ISI) Certification for Chemicals

Applicants have two Procedures to obtain the BIS License

Simplified Procedure

Please note the steps involved under this procedure:

Step 1: Applicant has to find the relevant Indian Standard and setting the In-house lab for testing of the product.

Step 2: Prepare the required documents along with test report (From the BIS Recognized lab) and submit the application in the BIS portal.

Step 3: BIS officer will conduct the factory Inspection.

Step 4: During Factory Inspection BIS officer sealed the sample and that sample further sent to the testing on BIS recognized lab.

Step 5: If any Non conformity issue is raised by BIS the same has to be rectified and complied by as instructed by BIS. If any

Step 6: ISI Certificate is granted by the Bureau of Indian Standard (BIS)

Duration – Approx 25 to 30 working days after submission of application in the BIS portal.

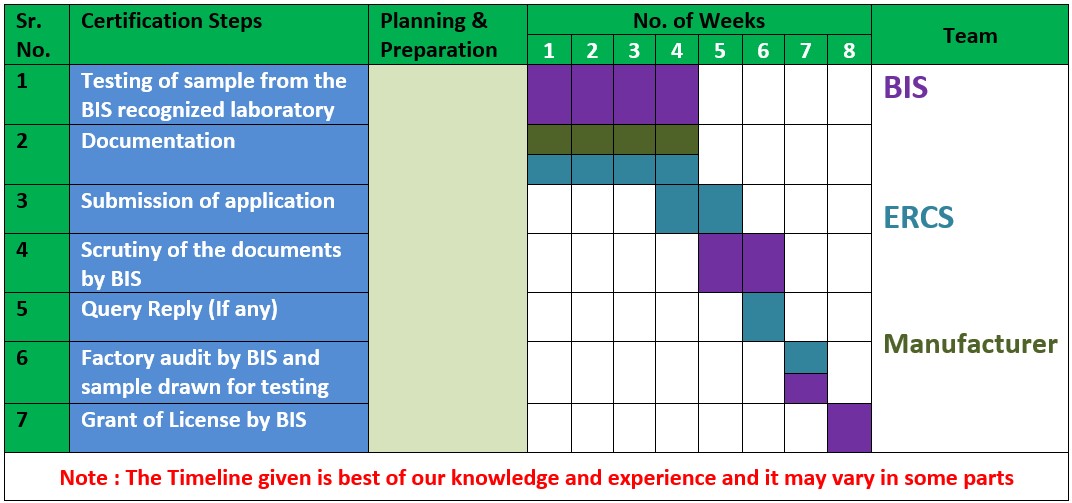

Project Time line Chart for ISI Certification of domestic manufacturer (Simplified procedure)

Normal Procedure

Please note the steps involved under this procedure:

Step 1: Applicant has to find the relevant Indian Standard and setting the In-house lab for testing of the product.

Step 2: Prepare the required documents and submit the application in the BIS portal.

Step 3: BIS officer will conduct the factory Inspection.

Step 4: During Factory Inspection BIS officer sealed the sample and that sample further sent to the testing on BIS recognized lab.

Step 5: If any Non conformity issue is raised by BIS the same has to be rectified and complied by as instructed by BIS. If any

Step 6: When the product passes all the test parameters then Bureau of Indian Standard (BIS) issue the ISI Certificate.

Duration – Approx 60 to 90 working days after submitting the application in BIS portal.

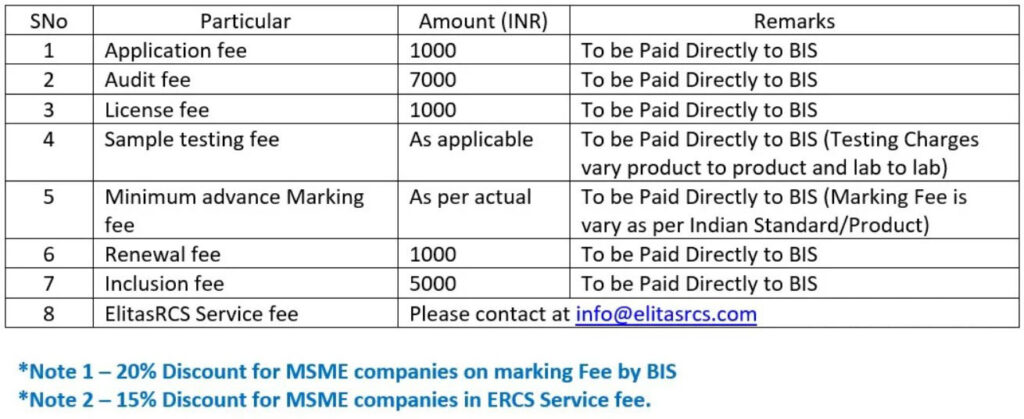

BIS Fee for BIS (ISI) Certification for Chemicals

Documents Required for BIS Certification for Chemicals

- Application form (Click here)

- Factory registration (KYC) Documents

- Manufacturing process flow chart.

- Required testing equipment list with valid calibration (In-house Testing Facilities)

- Raw material details and their test certificates

- Authorized signatory and QCI details

- Factory test report

- Plant layout and other related documents.

BIS Certification for Chemicals frequently asked questions (FAQs)

1. Where we submit the application to get BIS Standard Mark (ISI) on the product?

BIS accepts application for product certification in online mode only. Please contact us on info@elitasrcs.com for any type of assistance for obtaining the BIS Certificate.

2. Can we submit one application for different products being manufactured in the factory?

Separate application for each product / ISS is required to be submitted even for same factory / Manufacturing location.

3. Can we submit one application for same product being manufactured at the different factory?

Separate application for each product / ISS is required to be submitted even for same factory unit.

4. Which lab of test report will be acceptable in order to obtain the license under Simplified procedure / Option 2?

Separate application for each product / ISS is required to be submitted even for same factory unit.

5. What is th validity of test report under simplified procedure/ Option 2?

Test report will be valid up to 90 days from the date of issue of test report.

6. Does BIS carry any surveillance on my license regularly?

After grant of licence to the manufacturer, BIS can do surprise factory surveillance inspections through visit to the factory by certification officers of BIS or by personnel of the Agents appointed by BIS as per Rule 33 of BIS Rules, 2018.

BIS will verify that manufacturer continues to maintain the manufacturing infrastructure, process controls, quality control and testing formalities and conformity of the product to the applicable Indian Standard. Testing of the product samples in factory is also witnessed during the inspection.

Sample of ISI marked product is also drawn from the factory for verification of conformity to relevant ISS through third party laboratory testing. BIS also carries out market surveillance through purchase of samples of ISI marked product for verification of conformity of the product to relevant ISS through third party laboratory testing of the product.

7. What is the procedure to change the address or shift the factory location?

BIS licensee is required to inform BIS that they are shifting the factory location to a new address with relevant documents for the new premises similar to the documents submitted at the time of applying to BIS for grant of licence. The licensee can suspend the use of the Standard Mark under intimation to the Bureau on relocation of factory location to new location. The revocation of suspension may be done by the Bureau after verification of the old premises and verification of production process at new premises as per provision of paragraph 11 (3) & (4) of scheme I of BIS (Conformity Assessment) Regulations, 2018.